Description

YOUSUNLONG

Professional manufacturer of kitchen knives

YOUSUNLONG has been a OEM manufacturer of kitchen knives to Deutsche and United States for more than 15 years. Since YOUSUNLONG registered brand “順”. We are committed to providing users kitchen knives with elaborate craftsmanship and continuous pursuit of innovation in order to break the design and process constraints.

If you use our Kitchen knives you will like cooking and are willing to make delicious food to share with family and friends, our knives have become the choice of professional chef’s and home chef’s.

For sashimi, “one size fits all” is required.

For sashimi, “one size fits all” is required.

- Additionally, we have specially designed salmon knives of 11‘’ 13‘’ 15‘’ 17‘’different sizes for cutting large pieces of tuna and salmon.

- When cutting raw fish, it is necessary to cut it one at a time, one slice at a time, and never drag it.

- This is because the moisture of the raw fish will flow away in seconds after it is cut out.

- As long as the knife is sharp enough, the faster it can be cut, the more nutritious water can stay.

A great knife is made of high quality steel

- The core of the blade is high-hardness VG-10 “Super Steel” with a hardness rating of 60±2 on the Rockwell Hardness Rating.

- Hand ground edges at 15 degrees on each side for maximum sharpness and edge retention, ensuring precise slices every time.

Easy to carry at work and protects the blade at all times

- It can also effortlessly cut into extra-large pork shoulder, ribs, beef, salmon and tuna.

- It can be accurately cut, evenly sliced, dice, and bone removed, which is more convenient to use.

Balance is very important for a knife

- The material of the handle is 100% Natural Walnut which is healthier than the handle of chemical material.

- It is longer than a normal handle, which ensures a good sense of balance with the blade.

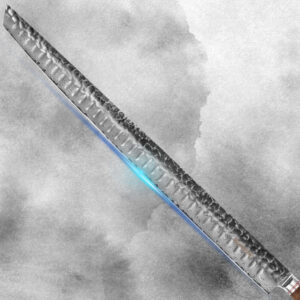

Genuine hand-forged Damascus knife have forged patterns on the surface

- Blacksmiths stack steel plates with different carbon contents in a row, cold forge, forge into a single steel plate, and then fold and forge repeatedly to achieve both the hardness of high carbon steel and the flexibility of low carbon steel.

- The blade surface retains the original hammering concave-convex effect. After manual hammering, a layer of concave-convex hammer pattern is formed on the surface, keeping the original calcination effect as black surface, more texture, better anti-sticking effect, reducing food and steel contact to keep ingredients fresh.

For sashimi, “one size fits all” is required.

For sashimi, “one size fits all” is required.

Reviews

There are no reviews yet.